What Happens To Wool After Shearing?

What happens to a sheep’s fleece after it is shorn? How do you go directly from the sheep to the wonderful to work with fiber that we all love to spin?

After shearing, wool is skirted, rolled, and bagged. It can be kept for home use, sold privately or sold to a wool processor to be washed and carded for use as spinning or felting fiber.

Raw Wool vs Washed Wool goes over the pros and cons of working with each.

Immediately after shearing wool is lightly skirted

As soon as the wool is completely shorn from the sheep, it is gathered up by the wool tender and taken off of the shearing platform to be skirted or bagged.

This is for two reasons, first it gets the wool out of the shearer’s way faster, keeping the working area clean, and it gives the wool tender the chance to skirt off any debris or dags (poo balls).

The fleece is skirted on a skirting table

The fleece is “thrown” on to a skirting table. This is a table with holes that debris can drop through. It may have a mesh top or be narrow boards that look more like a picket fence.

Most commercial wool is not skirted on a table, this is just for folks who are selling specialty wool that is worth the extra time and care during the busy time of shearing.

This skirting round will be quick and light, just to get the main offenders, if there are any, out of the fleece to reduce the likelihood of contaminating the whole fleece.

Anyone selling raw fleeces to customers would either have enough help on hand during shearing to do a thorough job of skirting the first time, or plan on lightly skirting after shearing and then going over the fleeces later for a final skirt.

In case you are wondering, the shearer does not handle the wool.

The shearer’s sole job is shearing, which gets the sheep out of the holding area as quickly as possible, the wool is handled by someone else.

Belly wool is skirted off during shearing

The belly wool of the sheep is generally tossed to the side during shearing.

Belly wool is short and usually to tangled up to make workable fiber, so it is pulled aside rather than getting mixed in with the prime parts of the fleece.

Skirted fleece is bagged

After skirting, the fleece is bagged. For selling commercial wool, the bags are huge and hold dozens of fleeces.

We have a bagging stand that is 8 feet or so tall and it holds a tall bag that we pack with fleeces, if we are on our game we can get 25 or so in a bag.

This is for commercial wool, for handspinning wool things are a bit different.

Once again the fleece will be bagged after skirting, but for selling direct to customers, the fleece will be put in an individual bag and in most cases labeled with a least the name or number of the sheep.

Bagged fleeces are send to processor

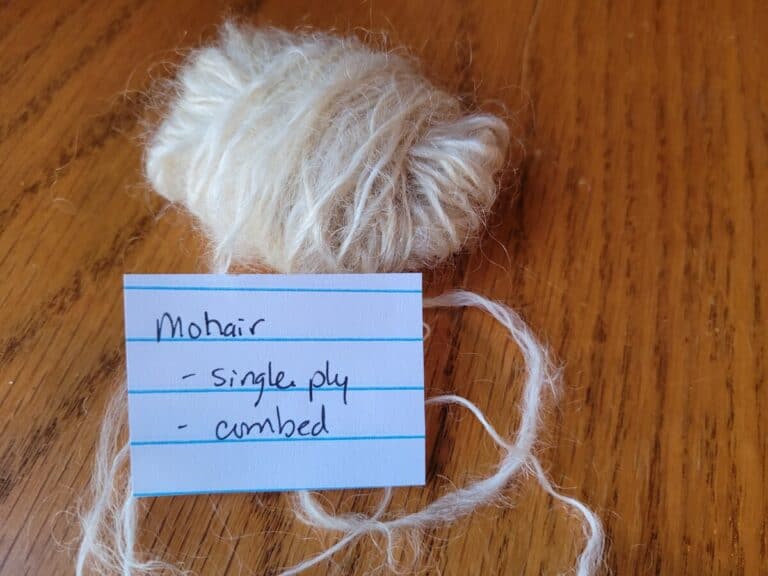

Bagged fleeces are sent to the processor to be washed and combed or carded out into roving or top.

The fleece that is sent is raw, of course, so quite a bit of the weight of the fleece is actually grease (lanolin), which will be washed out.

The clean fleece will then be dried and carded or combed, as requested.

The percent of clean fleece left is anywhere from 50-75% of the unwashed weight.

This means that if the unwashed fleece is 8 pounds, you can expect to get back around 60% or 4.8 pounds of washed and carded/combed fiber.

At this point the fiber is ready to be used by handspinners or any other wool loving crafter.

Processed fleeces are sold or used by owner

Once the fleeces come back from the processor, they are ready to be used or sold.

No other preparations are needed, unless, of course, the fleece is being sold in smaller amounts, then it needs portioned out.

You can buy a raw fleece and have it processed for you

Even if you do not have your own sheep, you can still have a fleece or two processed for you.

If you are considering processing your own wool, or getting a purchased fleece processed for you, you’ll be glad to know there are processors all over the country!

Search “wool processing mills near me” and see what comes up. I think you’ll be pleasantly surprised!

Fleeces can be stored

Fleeces can be stored until they are sold or used.

As wool gets older, two or three years older, it gets harder to use and loses it’s resiliency, but fleeces can be stored for a shorter time, just in the plastic bag until the buyer is ready.

To tell you the truth, the popular farms that sell direct to wool crafters do not store their fleeces, they are sold right away.

Raw wool can be used without processing

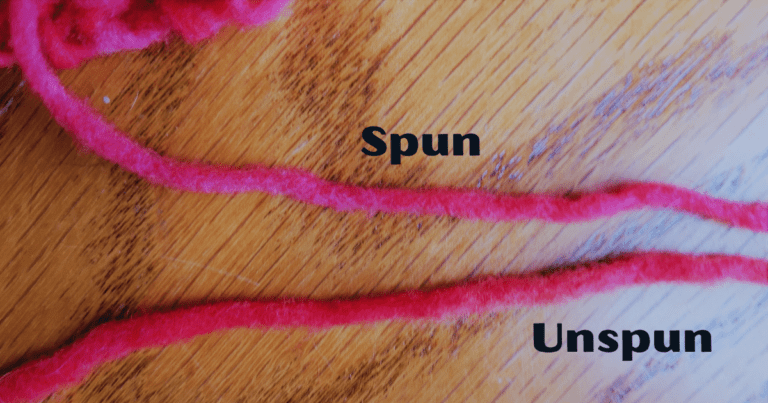

You can also use a raw fleece without processing, this is called spinning in the grease and is actually my preferred way to spin.

But the catch is that you have to choose fleeces that will work well with no prep, like carding, and plan to spin the yarn worsted, since you are not going to be carding the non washed wool.

Get Your Wool Ready To Spin In The Grease shows you how to work with an unwashed fleece.

You can wash the fleece yourself

You can wash a raw fleece yourself. You have the option to wash in smaller sections, like half a pound or so at a time or to wash a larger part of the fleece, up to the whole fleece, at once.

I have trouble getting the whole fleece to dry, since I usually wash them during the humid summer, but washing and drying smaller sections is fast and easy.

Raw wool is worth $0.25-$150 per fleece

There is a huge range of wool prices, commercial fleeces from normal medium wooled production sheep are worthless, by that I mean we pay $5 for shearing and get $0.25 per fleece when it’s sold.

Obviously, we are not making money with the wool!

The shearing is more than paid for by the price bump (right now, about 4x) we get for selling wool lambs. Which means, we actually have meat sheep that have wool.

For any farmers raising wool sheep for wool, they are getting significantly more money per fleece. And rightly so, this is just supply and demand establishing a higher price for a good that folks want.

Depending upon how popular the breed is, how nice the specific fleece is and color prices of raw fleeces are anywhere from $75-150 for the whole fleece.

Some folks sell partial fleeces, which will generally be for higher priced fleeces.

Where To Sell Your Wool? is an article on my livestock site showing sheep farmers where to sell their fleeces.